What is COPQ Cost of Poor Quality?

29 Aug

To overcome these barriers, the company must assign individual responsibilities and accountability. Indeed, engaging employees in quality improvement discussions can foster a positive approach towards such measures. Therefore, these costs are treated as anticipated investments made by the firm to minimize quality errors before occurring. Developing a clear strategy is crucial for implementing prevention costs effectively.

Analyzing the Cost of Poor Quality Data

It includes also the preparation of procedures needed to communicate these plans to all concerned. That was in 1994, long before quality management tools like Quality Management Systems (QMS) were widely available. According to Feigenbaum (who developed the Total Cost of Quality formula that captures the costs of good and bad quality), every factory has an evil parasitic twin.

Relationship Between Actual Costs & FP&A in Manufacturing

The important thing is that it is considered when any decision is being made about quality and customer satisfaction. Before mass production begins, the company might have inspectors on site who are charged with ensuring that every vehicle meets certain requirements before it leaves the premises. If defects are found, companies can either fix them or scrap the cars that contain them and lose millions of dollars in revenue.

- This includes leadership commitment, employee empowerment, and recognition programs.

- Examples include inspection and testing, quality audits, quality control equipment, and rework or retesting of defective products.

- By tracking changes in customer satisfaction before and after implementing prevention measures, companies can gauge the impact of their investments on customer perception and loyalty.

- To help you arrive at some estimates, we’ve reduced the range of prevention operations to four key categories, each with their sub-costs.

Mastering ISO 9001:2015 Quality Management System (Accredited)

Indirect costs are harder to connect and estimate like lost sales or customer dissatisfaction. Evaluating the magnitude of indirect vs direct costs highlights the greater business impact of quality beyond operations. Once the cost of poor-quality data has been collected, it needs to be analyzed to identify opportunities for improvement. Examples include inspection and testing, quality audits, quality control equipment, and rework or retesting of defective products. While 58% of respondents in Gartner’s survey [2] (only) tracked their costs of poor quality, a mere 3% (only) tracked their costs of prevention and appraisal.

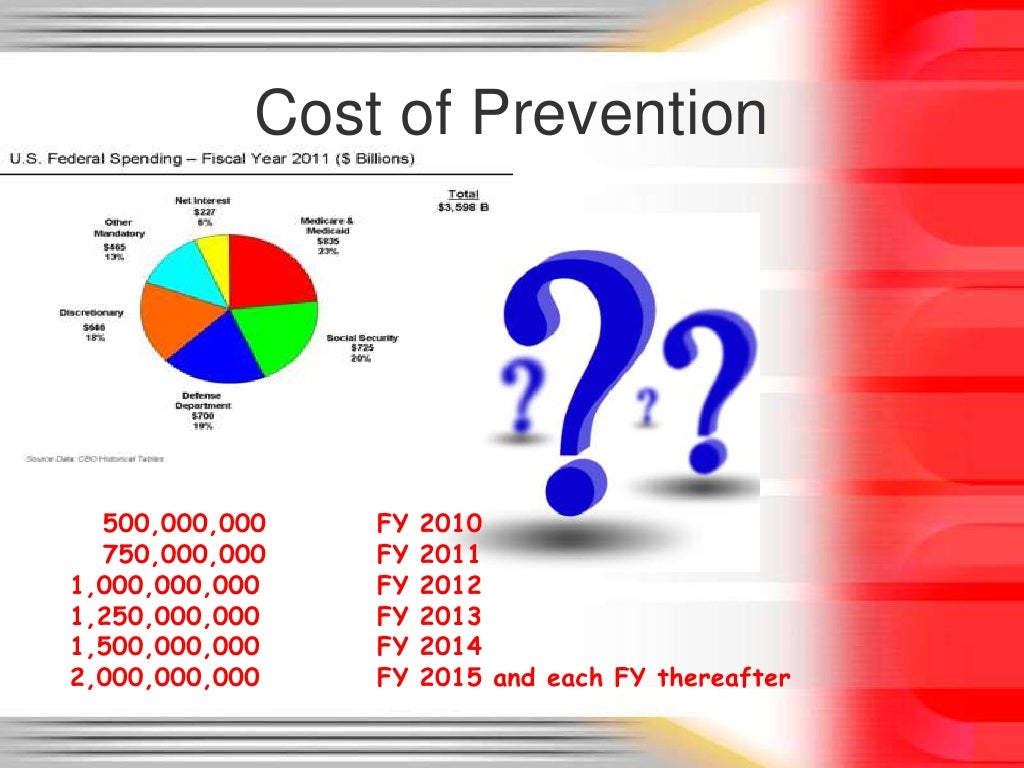

Prevention costs can also help reduce the cost of production and improve profitability. Companies can measure the cost savings achieved by comparing the total investment in prevention to the cost of quality before and after implementing prevention measures. Implementing prevention costs requires resources such as time, personnel, and finances. Companies should ensure that sufficient resources are available to implement preventive measures effectively. Implementing prevention costs effectively requires a clear understanding of the preventive measures and their impact on the business.

What Are the Consequences of Neglecting Prevention Costs in a Business?

These costs are part of a proactive quality management approach aimed at identifying and eliminating potential issues before they occur. Understanding prevention costs is crucial for learners in business and management to grasp the importance of quality assurance and its impact on overall business performance. In conclusion, prevention costs are an essential aspect of business management, crucial in ensuring customer satisfaction, improving product and service quality, and maintaining a competitive edge. By investing in prevention costs, companies can reduce the occurrence of defects and other quality issues that could lead to costly repairs or customer dissatisfaction. Measuring the effectiveness of prevention costs is an essential aspect of evaluating the success of an organization’s risk management program.

The strategy should outline the required preventive measures, resources, and expected outcomes. The strategy should also identify potential challenges and how they will be addressed. It is important to note that while prevention costs may seem more proactive and beneficial to the business, appraisal costs are equally important.

By using preventative measures that identify and fix problems before they happen, the company can gain a competitive edge and increase profits by focusing on quality control. Lean Six Sigma prevention cost analysis (PCA) is an important tool that can help businesses prevent costly mistakes and improve their bottom line. By taking the time to analyze the potential costs of problems before they occur, businesses can make better decisions and avoid some of the pitfalls that can damage their profitability. This article will explore the benefits of Lean Six Sigma PCA and explain why it is relevant to businesses. Internal failure costs are incurred when defects are discovered before the product or service is delivered to the customer, such as rework and scrap.

In addition, these costs aim to provide a solid quality management system by minimizing the occurrence of quality issues. Changing the business environment, such as a shift in the market, new regulations, or a change in customer preferences, can necessitate reviewing and revising prevention cost strategies. Such changes can affect the company’s operations, and it is essential to ensure that prevention cost strategies are still relevant and practical. Here are the best practices for implementing prevention costs in an organization. Here are some common challenges companies face when implementing prevention costs.

By investing in prevention costs, organizations can reduce the need for appraisal costs and overall quality-related expenses. A balance approach that emphasizes prevention while maintaining effective appraisal practices can lead to improv quality, higher customer satisfaction, and greater long-term success. Thanks to this information, the company knows what its potential savings may be. One of the primary challenges companies face when implementing prevention costs is the cost of implementation. Preventive measures such as employee training, equipment maintenance, and quality control assessments require a financial investment. Smaller businesses may struggle to allocate funds to these preventative measures, while larger companies may struggle to implement prevention costs across multiple departments or locations.

In organizations focusing on manufacturing or service delivery, the responsibility for implementing prevention costs may fall under the operations department. This department ensures that products and services are manufactured to a high-quality standard. By investing in quality control measures, businesses business accounting policy manual can identify and eliminate production errors that may result in defective products. This can help ensure products are manufactured to a high-quality standard, improving customer satisfaction and loyalty. Another challenge that companies face when implementing prevention costs is resistance to change.